Excavator bucket teeth can be said to be a love-hate part, on the one hand, bucket teeth as the pioneer of the bucket, so that excavators shovel soil, rock, ditching invincible. On the other hand, the bucket teeth wear out quickly, the replacement frequency is high, and the cost increases so that diggers are heartbroken! Why is the price of similar bucket teeth, others always use a longer time than you? Why do you spend a lot of money to buy the bucket teeth, sometimes it is not as cheap as the previous one? Why is this? I'm going to reveal it to you! Let's talk about those things about bucket teeth.

●Earth teeth (for excavation of dirt, sand, gravel and other light operating environment) general earth teeth with a larger bucket mouth area, with a larger stacking surface, so it has a higher filling factor, save operating time, high efficiency.

● Rock teeth (for ore, quarry) Ore loading after blasting, etc., heavy work strength wear-resistant steel, better excavation performance and more economic.

● Conical teeth (used in coal and underground mining) are mainly suitable for drilling rock formations that are not very hard and have a large impact.

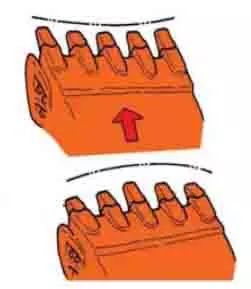

The common installation methods are direct-mounted bucket teeth and cross-mounted bucket teeth: direct-mounted means the pin is installed vertically with the front of the bucket teeth, and cross-mounted means the pin is installed parallel with the front of the bucket teeth.

It is more convenient in disassembling, smashing directly from above, and has a large operating space.

In the excavation, the straight mounted gear pin will be subjected to the squeezing pressure of the excavated material, if the excavation force is large, then the clamping force of the spring cannot meet the requirements, which will easily lead to the gear pin falling off, so this structure, although easy to disassemble, is generally used in smaller excavators and lower tonnage excavators.

It is not too convenient to disassemble, and the side operation space is small, so it is difficult to give force. When removing individual bucket teeth, they must be disassembled in order using special long-rod type tools.

When digging, the front side of the cross-mounted gear pin will not be subjected to the squeezing pressure of the excavated material, so it can withstand a larger digging force, but when the spring is subjected to reciprocal lateral force in use, it will easily wear out and fail, thus causing the gear pin to fall off. Generally in the excavation force of more than 20 tons is more common.

Sand casting is the lowest cost, and the level of technology and quality of gears are not as good as precision casting and forging casting. Therefore, the price is the cheapest among all processes.

Precision casting: The cost is moderate, but the requirements for raw materials are very strict and the technology level is high. Some of the precision casting gears are even better than forged cast gears in terms of wear resistance and quality due to the ingredients. At present, precision casting is the mainstream manufacturing process of bucket teeth in the market.

(Note: If the number of teeth is large, then the cost performance of the teeth is very high, precision casting teeth are very good in terms of price, quality, cost performance and wear resistance)

Forging casting: is the highest of the three processes, the level of technology and the quality of the bucket teeth is also the best, so the sales price is also the most expensive, but can guarantee that the industrial level and quality of forging casting bucket teeth is the most excellent!

(To the point: if the excavator is doing earthwork, the annual replacement frequency and demand for bucket teeth is relatively small, it is recommended that you choose forged and cast bucket teeth, although the price is much higher, but the service life, production process and quality are optimal)

Generally, forged bucket teeth are more wear-resistant and harder, and their service life is about twice as long as cast bucket teeth, while the price is about 1.5 times of cast bucket teeth.

The replacement cycle of bucket teeth depends on the construction environment and the degree of wear of the bucket teeth, for example, if the excavator has been doing earthwork, then the degree of wear of the bucket teeth is relatively small, usually about 4-5 months to replace once.

If it is a rock bucket replacement bucket teeth frequency is faster, like granite is generally about a week to replace the bucket teeth, of course, this cycle is not fixed, according to the quality of the bucket teeth, the actual operation of the degree of care to determine the frequency of replacement of bucket teeth.

1. Keep sharp: the bucket teeth on both sides of the excavator generally wear about 30% faster than the bucket teeth in the middle of the bucket, when both sides of the bucket teeth than the middle of the bucket teeth wear much shorter, the two sides and the middle of the bucket teeth interchangeable position to continue to use, indirectly increase the service life of the bucket teeth.

Tips: If there is a 2~3cm difference between the center bucket teeth and the two end bucket teeth, you can swap them.

2. Digging operation angle to pay attention to: bucket teeth down digging perpendicular to the work surface, to avoid breaking bucket teeth due to excessive inclination.

3. Wear of the tooth seat: When the tooth seat wears off 10-15%, it is recommended to change the tooth seat. The large gap between the tooth seat and the bucket teeth that wears off will cause the bucket teeth and the tooth seat to change and cause the bucket teeth to break due to the change of the force point.

4. Pay attention to the driving method: excavator driving method to improve the utilization of the bucket teeth is also very critical, excavator drivers try not to collect the bucket when lifting the big arm, if the driver raises the big arm while collecting the bucket so that the operation will make the bucket teeth subject to an upward traction, so that the bucket teeth from the top tear, thus tearing the bucket teeth, this operation action to pay special attention to the coordination of action. Some excavator drivers tend to use too much force in the action of enlarging the arm and sending the small arm, the bucket quickly to the rock "knock" or force the bucket to fall on the rock, which will shatter the bucket teeth, or easy to knock the bucket on the crack, the size of the arm knocked bad.

Excavator master in the operation of the angle of digging operation should pay attention to try to dig when mastering, bucket teeth down digging perpendicular to the work surface, or outward inclination angle of not more than 120 degrees, to avoid breaking bucket teeth due to the angle of inclination is too large. Also pay attention not to swing the digging arm left and right under the condition of large resistance, which will make the bucket teeth and tooth seat break due to excessive force left and right, because the mechanical design principle of most models of bucket teeth does not consider the design of left and right force.

5. Buying guide: If the excavator is doing earthwork, the frequency and demand of replacing bucket teeth every year is relatively small, then it is recommended to choose forged and cast bucket teeth, although the price is much higher, but the service life, production process and quality are the best.

If the number of bucket teeth is relatively large, then the cost performance of the bucket teeth is required, then the precision casting bucket teeth are very good in terms of price, quality, cost performance and wear resistance.

The more commonly used imported excavators on the market are: Carter, Komatsu, Hitachi, Daewoo, Kobe Steel, Hyundai, etc.

Small reminder: buy bucket teeth is definitely not as simple as handing over money with one hand, choose a good, excavator, bucket and the completion of the project work have quality assurance, if you do not buy the right, light Figure of cheap, resulting in the use of a short period of time easy to bad becomes a matter of course!